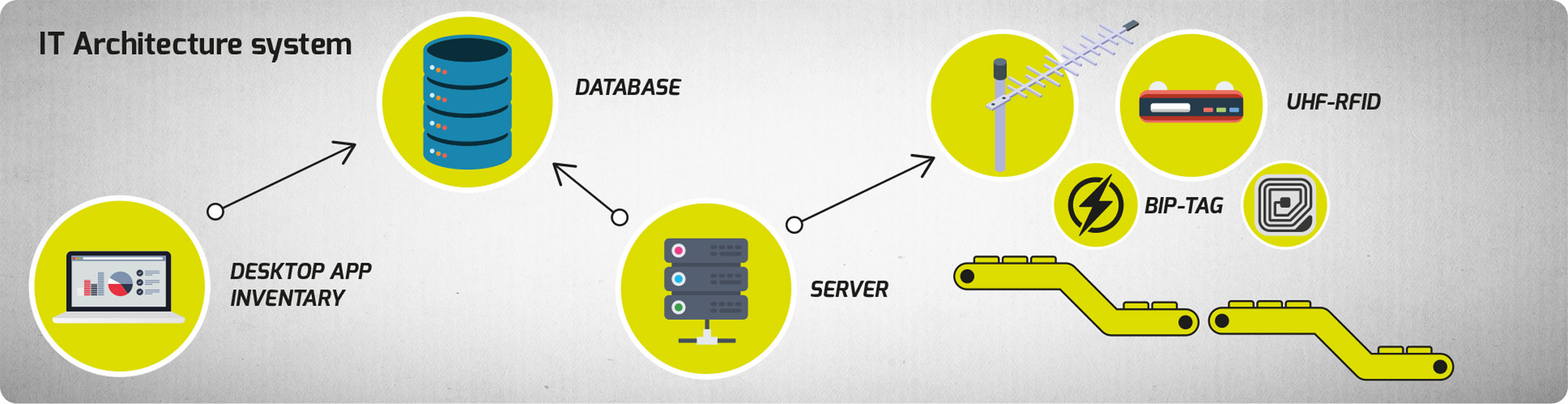

The mineral traceability system enables the tracking of the blasted material from the production face, through loading and hauling, and on the conveyor belt after crushing.

The system can associate the crushed material with the blast of origin and existing granulometric information.

This association is made through an arrangement of antennas installed on the conveyor belt which identify the tracking devices and subsequently assign the material’s attributes to them, based on their unique ID’s.

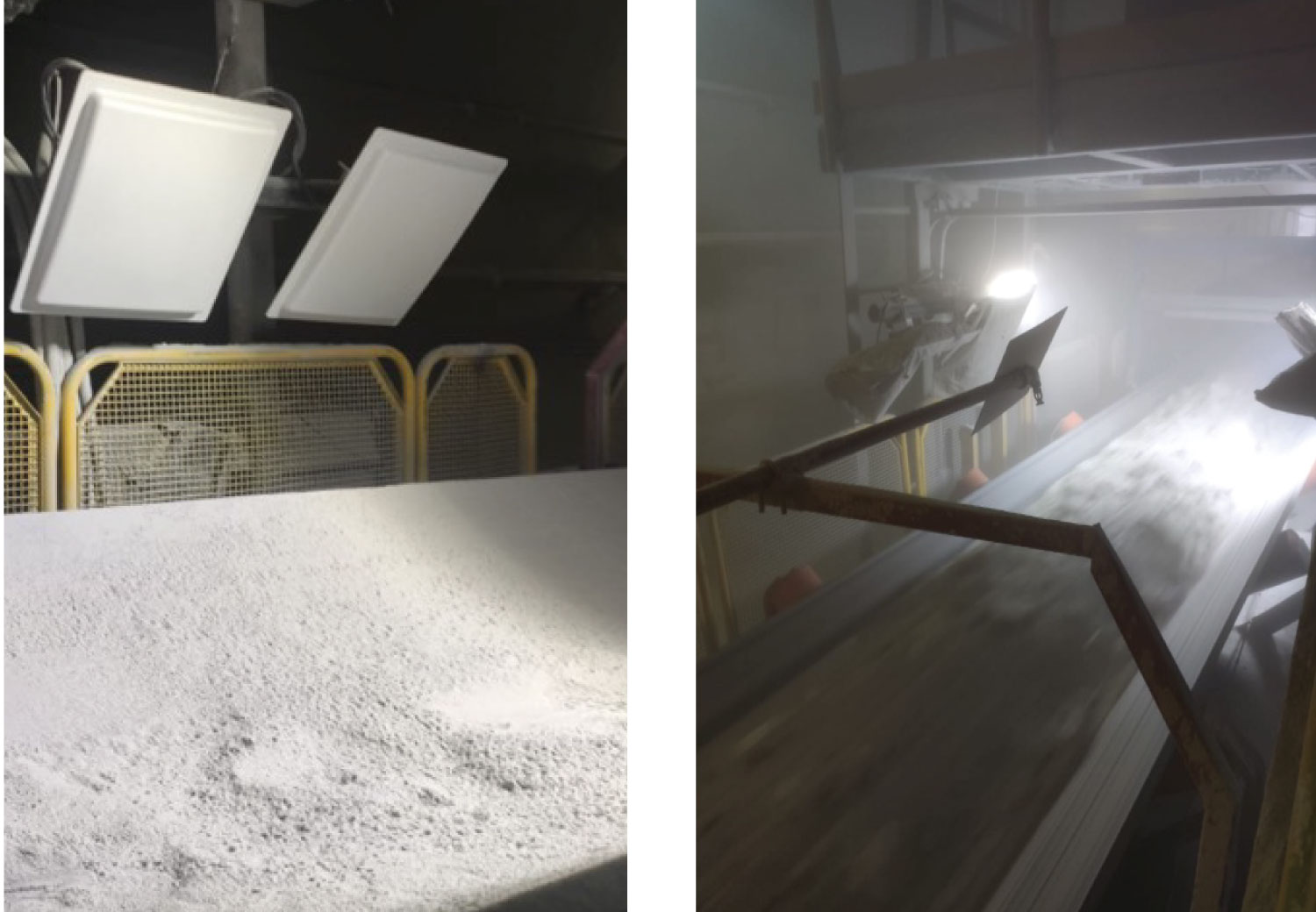

Tag Devices

The source device is a TAG card embedded in spherically-shaped, highly resistant resin or polymer.

Sensors are designed and manufactured with materials highly resistant to all shocks, friction and compression, in order to withstand the extreme conditions observed during blasting.